The value n is dimensionless, but C has units of either (in/cycle)/(ksi√ in ) n or (mm/cycle)/(MPa√ m ) n. Where C is an intercept constant and n is the slope on a log-log scale. This straight-line region is shown in the figure within region II, and it is defined by the Paris curve:

On a log-log plot, there is typically a straight-line region of da/dN over a range of ΔK values. In this figure, the growth rate and the stress intensity range are plotted on a log-log scale. Note that if the definitions for maximum and minimum stress intensity are substituted into the definition for the stress intensity range, a new, useful definition for stress intensity range can be obtained:Īnother useful relationship can be derived by combining the equations for stress intensity range and R-ratio:

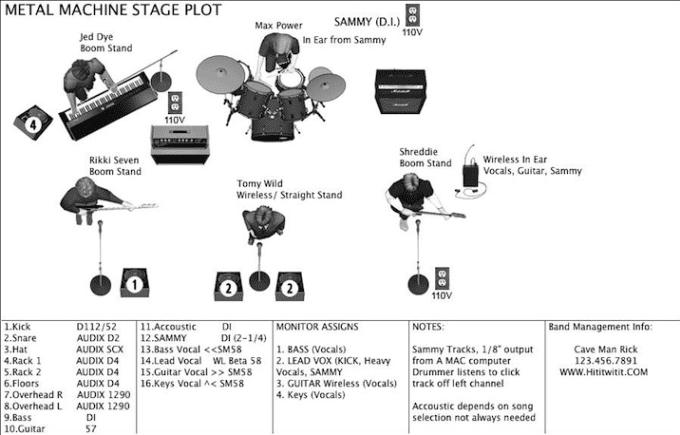

#Stage plot pro full cracked crack

The values Y and a are dependent on geometry, so for a specified crack and part geometry, the stress intensity factor is proportional to applied stress. Where σ is the applied stress, a is the crack size, and Y is a dimensionless geometry factor that is dependent on the geometry of the crack, the geometry of the part, and the loading configuration. Recall that the stress intensity factor is a function of geometry and applied stress: The stress ratio R is commonly called the R-ratio. The stress ratio is an important quantity, and is the ratio of the minimum stress to the maximum stress: In the figure, σ max is the maximum value of applied stress, σ min is the minimum value of applied stress, σ m is the mean stress, σ a is the stress amplitude, and Δσ is the stress range. The rate of crack growth is da/dN and is the instantaneous slope of the crack growth curve. The crack size, a, is shown as a function of cycles, N, of applied load. If you are not familiar with fracture mechanics, it is recommended that you read that page before proceeding.Ī typical plot showing the growth of a crack is provided below. The analysis of fatigue crack growth relies on the concepts of fracture mechanics which are discussed on this page. Crack growth in a hostile environment is called environmental crack growth and is not discussed here. Crack growth due to cyclic loading is called fatigue crack growth and is the focus of this page. They usually start off small and then grow during operational use.Ī crack in a part will grow under conditions of cyclic applied loading, or under a steady load in a hostile chemical environment. Cracks typically form around pre-existing flaws in a part.

0 kommentar(er)

0 kommentar(er)